- About Us

- Lines

- Applications

- News

- Contacts

- Lingua

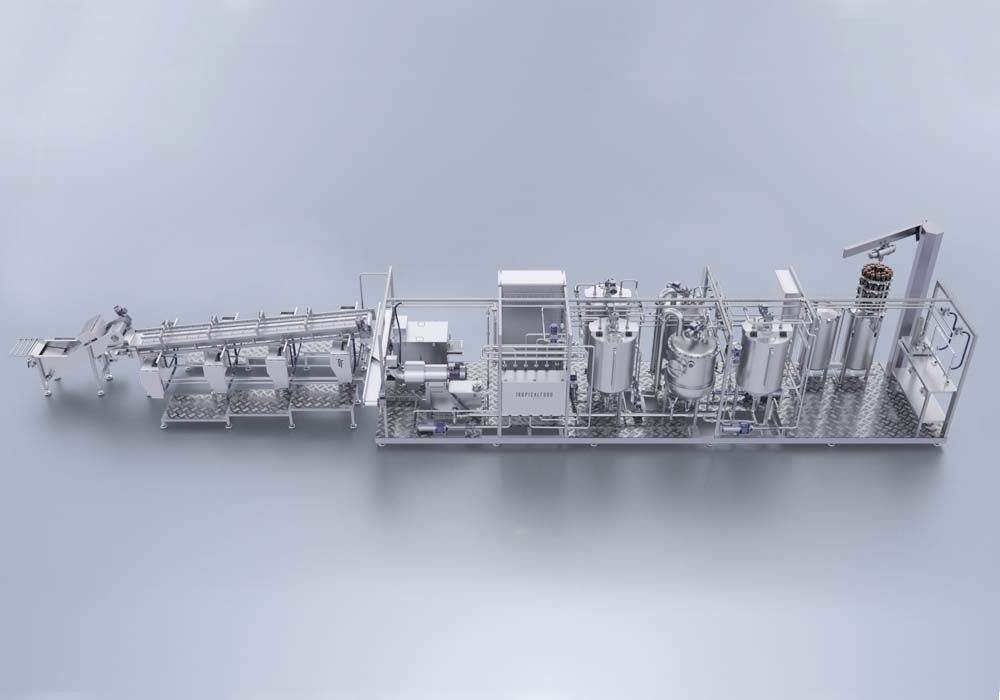

MINI INDUSTRY LINE 200

Mini Industry 200 is a small multi-fruit line designed for small producers or farming cooperatives who want to produce wholemeal juices, concentrates, nectars, jams, sauces, and gravies.

A wide range of products can be processed: thick-skinned fruit (pineapple or citrus), stone fruit (mango, peach, apricot), fruit with seeds (passion fruit, apples, pears, etc.), small fruit (berries) and tomato. The Line consists of a washing, sorting and first manual processing unit and a single module with pulp extraction and refining machines, formulation tanks for recipes or product cooking, manual filling, and pasteurization area on various packages (glass bottles and jars, cans or doypacks).

Its complete adaptability in terms of size, costs, energy consumption and variability of the finished product is supported by TFM technology and can also be particularly suitable for research and training projects in food companies or institutes.

Line capacity:

from 200 Kg/h up to 400 Kg/h of fresh fruit or tomato.

production process

|

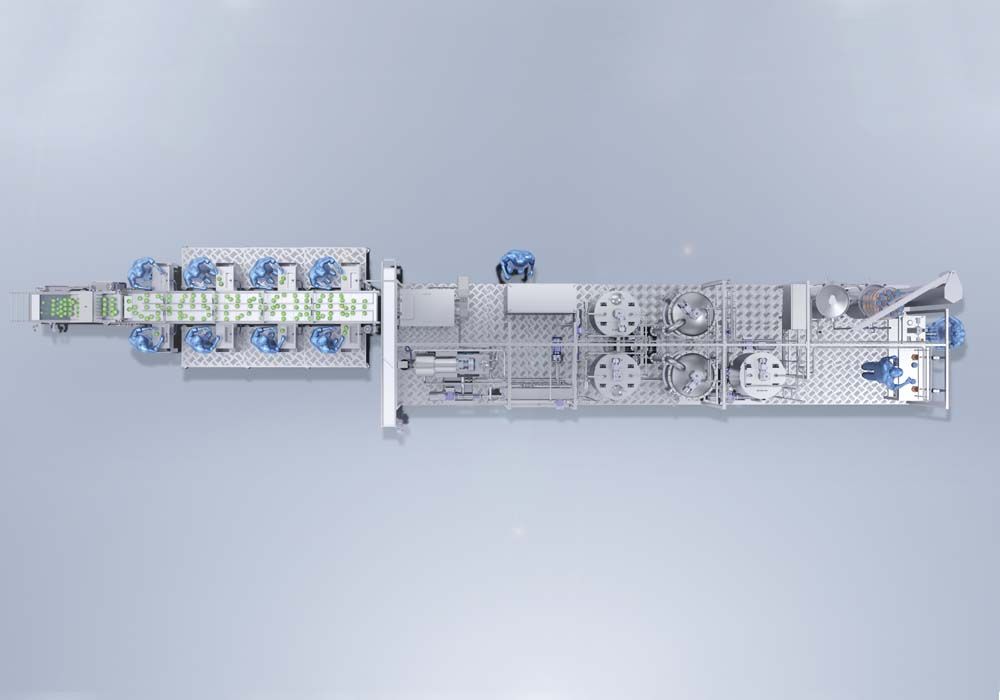

Fruit pre-treatment area |

Washing Machine Selection belt/First manual processing with 8 platforms for the operators |

|

Pulp Extraction and Refining Area |

Extractor with Beaters ARTEMIDE Turbo Shredder and Refiner HERA Orange Juice Extractor (optional) Preheater EBE |

|

Formulation Area |

1 or 2 Formulation Tanks with the possibility of adding ingredients 1 or 2 Steam concentrators for cooking or making concentrates / jams 1 collection tank for the finished product |

|

Filling and Pasteurization Area |

2 Manual Filling Stations with capping machine and seamer 2 Pasteurization autoclaves Optional: alternatively, an automatic filling machine with pasteurization tunnel can be installed. |